MES-Driven Digitalization in Automotive Stamping Industry: A Case Study of Tandem Press Line

Keywords:

Automotive Stamping, Digital Transformation, Green Field Implementation, Industry 4.0, Manufacturing Execution System (MES), Smart Manufacturing, Tandem Press LineAbstract

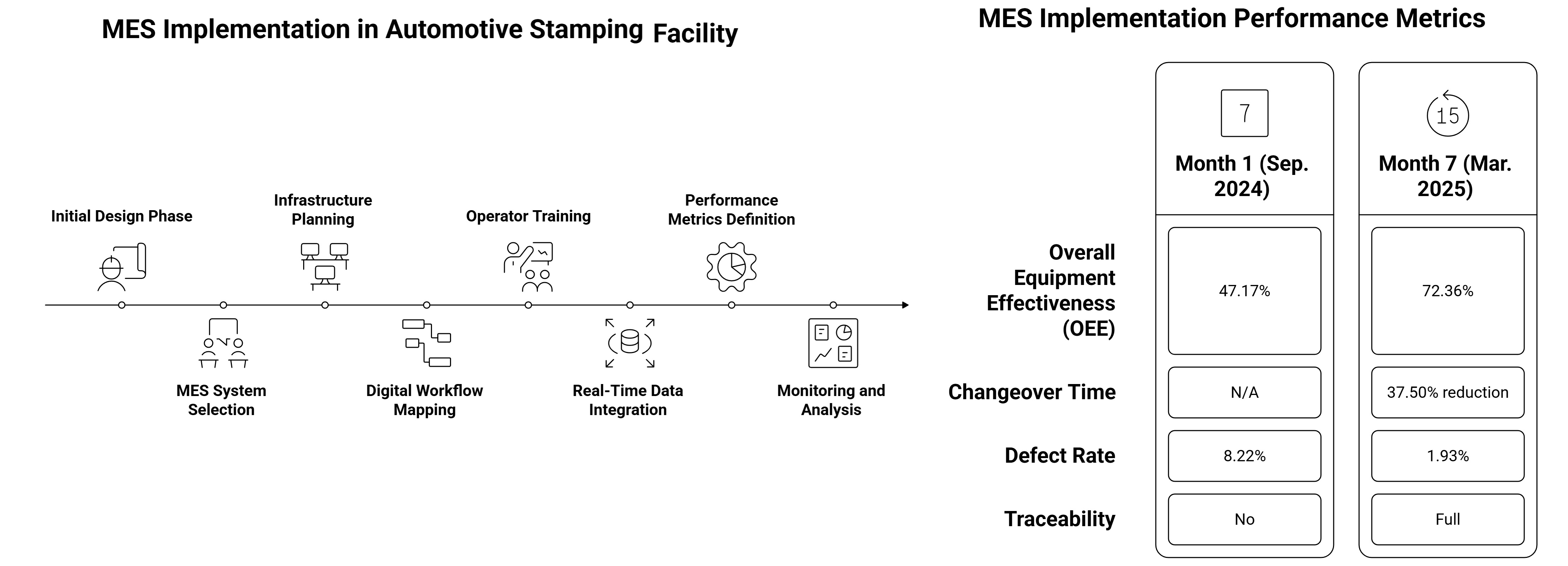

The rapid evolution of smart manufacturing technologies has made Manufacturing Execution Systems (MES) central to improving efficiency, traceability, and quality in discrete manufacturing. This work investigates the end-to-end implementation of an MES solution in a newly established automotive stamping facility featuring a Tandem Press line. The objective is to explore how MES can be embedded from the initial design phase to achieve operational excellence in a green field manufacturing environment. A structured case study methodology was adopted, encompassing tandem press line layout design, MES system selection, infrastructure planning, digital workflow mapping, operator training, and real-time data integration with press automation systems. Performance metrics such as Overall Equipment Effectiveness (OEE), traceability, changeover time, and quality rate were defined during commissioning and monitored for seven months post-deployment. The MES implementation led to early stabilization of production parameters, with an OEE ramp-up from 47.17% in Month 1 (Sep. 2024) to 72.36% by Month 7 (Mar. 2025). Real-time visibility enabled a 37.50% reduction in changeover time and defect rate reduced from by 8.22% to 1.93%. Full digital traceability was achieved across material, machine, and operator layers from the first batch onward. The findings offer a replicable digital blueprint for MES integration in green field projects across the automotive stamping sector and other high-volume manufacturing domains. MES, when integrated from inception, transforms plant commissioning from a sequential execution into a data-driven optimization loop, accelerating productivity, standardization, and digital maturity from Day One.Downloads

Download data is not yet available.

Downloads

Published

2026-01-05

How to Cite

Bachhav, P. D. ., Patil, S. M., Jadhav, M. S., & Kene, H. D. (2026). MES-Driven Digitalization in Automotive Stamping Industry: A Case Study of Tandem Press Line. Science Essence Journal, 42(1), 14–49. Retrieved from https://ejournals.swu.ac.th/index.php/sej/article/view/17059

Issue

Section

Research Article